Dalli’s history

We have long regarded sustainable and socially responsible business practices as a key prerequisite for our success. We offer products and processes that meet the highest standards. We attach the greatest importance to safety, quality and the environment throughout the entire product life cycle.

We are regularly checked by a large number of internal and external audits and inspections by the authorities to ensure that we are implementing our sustainability concept. In addition to system certifications, there are also various product-related standards such as those of the BDIH, NATRUE and daab. We follow all of these and have consciously signed up to them.

1845

Company foundation

Foundation of the company in Stolberg in the Rhineland

Start of soap production

Construction and installation of the first boiling kettle for soap production for laundry and body care soaps. Delivery and distribution of the soaps in the company’s own shop and via handcarts and horse-drawn carts.

1867

Specialisation and expansion of soap production for the textile industry.

1868

Licence granted to a Paris-based company

1885

Start of powder production

Start of washing/soap powder production under the name DALLI-SEIFE. Modern and progressive, the factory’s own electricity is generated by a hydropower-driven turbine

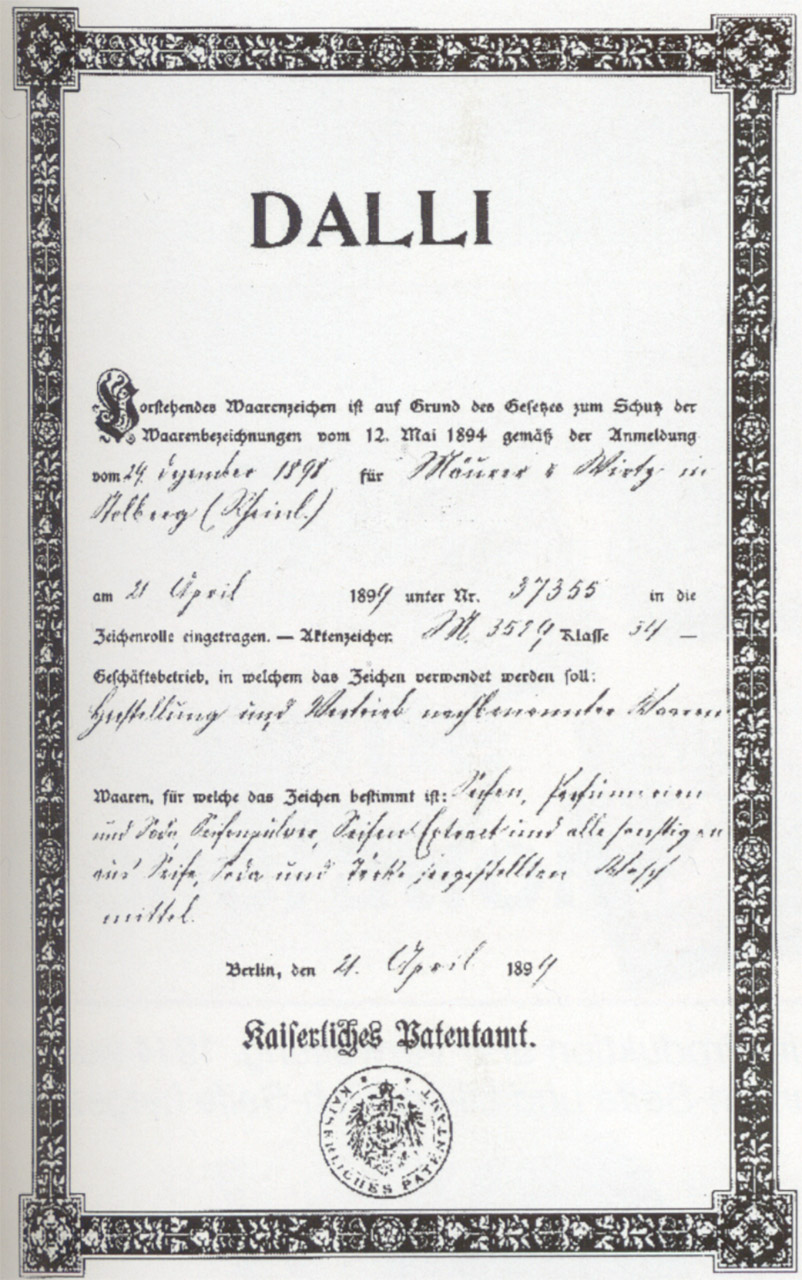

1899

Dalli becomes a brand

The name “dalli” is registered and protected as a trade mark at the Imperial Patent Office. As early as 1890, the company has its first telephone connection.

1909

Company moves to its current headquarters

Acquisition of a new company site in Zweifaller Strasse in Stolberg in the Rhineland – not far from the former company headquarters. A pioneering move at the time, typewriters are used as early as 1904 and the company employs its own advertising specialist.

1913

Start of industrial mass production

By investing in the very latest technology, the site was converted into a modern large-scale operation, which already employed 150 people at the time.

The increased demand led to the opening of the (first) branch in 1910 and by 1912 the first lorry was driving dalli products to its customers.

1938

Acquisition of two soap production facilities

Takeover of two soap factories in Berlin and Vienna. The company grows and has more than 700 employees at this time.

1960s

Entry into the private label business

The production of the “Tandil” brand for the retail customer Aldi laid the foundation for private label production.

1970s

Expansion of the private label business

The positive business development led to the expansion of the production facilities in Stolberg, which now employ around 2,000 people.

Investments were made in facilities for employees on the company premises, such as a company canteen, a health centre, a social building and a company library.

1979

Expansion of laundry care expertise

Acquisition of NICCO-Werk GmbH, based in Bonn-Beuel, to expand the brand and product range for laundry care.

1992

Takeover of a Dutch detergent factory

Acquisition of the detergent factory and brand De-Klok in Heerde, the Netherlands, to strengthen the brand and private label business with over 100 employees.

1995

Further expansion course

Takeover of Dutch company DICOM B.V. and Reinelt Produktions-GmbH with sites in Heerlen-Hoensbroek, Friedberg and Westerburg, each with around 150 employees, to expand the product range.

1997

Expansion of beauty care

Acquisition of the cosmetics and body care manufacturer WIN COSMETIC GmbH & Co. KG in Flörsheim-Dalsheim with around 270 employees.

2001

Expansion of the body care spectrum

Foundation of CULT COSMETIC GmbH & Co. KG at the Weinheim site.

2002

Expansion of the aerosol business

Foundation of WIN AEROSOL GmbH & Co. KG at the Westerburg site.

2007

Entry into the natural cosmetics business

Takeover of CEP Cosmetic Entwicklungs- und Produktionsgesellschaft mbH from Salzhemmendorf.

2010

Entry into the industrial business

Takeover of a Spanish bleaching production facility with almost 70 employees.

2012

New washing powder plant

Acquisition of a washing powder production facility in Warth, Austria, with more than 60 employees.

2012

Withdrawal from bleaching production

Withdrawal from the Spanish bleaching market and simultaneous sale of the Spanish production plant.

2015

Expansion into Romania

Takeover of a production facility in Timisoara (Romania) with more than 195 employees.

2017

Expansion of the private label business

Expansion of the brand business to include the brand rights to DASH for Germany, Austria and Switzerland and acquisition of the brand rights to BONUX in geographical Europe (excluding Turkey) with a focus on the Eastern European market.